How to Safely Inspect Machinery Damage Without Risking Electrical Short Circuits

Too often, when machinery is damaged, people without proper knowledge attempt to restart it to check whether it still works.

This is a critical mistake.

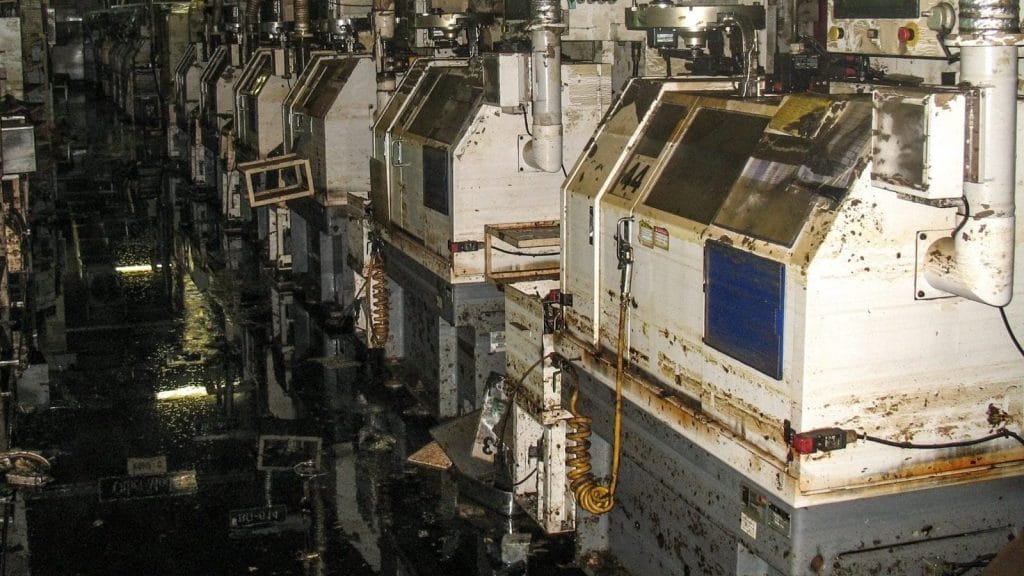

Attempting to switch on damaged machinery, especially after incidents such as flooding, can lead to severe and even life-threatening consequences. Proper inspection should always be carried out by professionals to ensure safety and to prevent further loss of both lives and assets.

This article provides safe preliminary guidelines and steps for assessing machinery damage, enabling you to better understand the situation before expert intervention.

Why Immediately Restarting Machinery After an Incident Is Dangerous

When unexpected events such as flooding, fires, or other disruptions occur, never attempt to restart machinery right away. Doing so poses serious risks to both individuals and the machinery itself. Forcing the equipment to run may worsen the damage.

Key factors that make restarting immediately unsafe include:

- Hidden Moisture

Moisture trapped inside machinery is one of the biggest risks. It can cause short circuits, damage control panels, or compromise lubricants, leading to excessive friction when the machine is operating. These issues often result in higher repair costs and more extensive damage.

- Conductive Contaminants

Floodwater, rainwater, mud, saltwater, or certain chemicals often contain conductive minerals. When these substances remain on machinery surfaces, they can cause short circuits, electrical leakage, or distorted readings during inspections. This creates unnecessary complications and increases the risk of recurring failures.

- Deteriorated Insulation

Events like fires, floods, or oil contamination can corrode or weaken insulation materials. Once insulation is compromised, it increases the risk of electrical sparks or accelerated wear. Restarting machinery in this condition can cause immediate hazards.

5 Steps for Safely Conducting a Preliminary Machinery Inspection

While the most reliable way to assess damage is to engage experts, you can perform an initial safety check to document the condition before specialists arrive. Follow these five essential steps:

1. Completely Disconnect Electrical Power

Cut off all power supplies to prevent short circuits or electrocution. Lock out switches, valves, and power sources to eliminate the risk of leakage or accidental restarts.

2. Conduct a Visual Assessment

Inspect the surrounding area for hazards such as standing water, leaking oil, spilled chemicals, or building debris that could compromise machinery safety.

3. Check for Moisture and Leakage

Look for visible signs of dampness, seepage, or water residue. Do not touch, operate, or attempt to dry the machinery yourself, wait for experts to properly assess and handle it.

4. Document and Record Evidence

Collect as much information and photographic evidence as possible. Avoid moving or altering machinery and surrounding damage. This documentation is valuable for professional assessment and crucial for insurance claims.

5. Do Not Attempt Cleaning or Repairs Yourself

Cleaning or repairing machinery without proper expertise can cause more harm than good. Hidden damage may worsen, repairs could void insurance claims, and in extreme cases, improper handling could be fatal.

Why Machinery Damage Assessment Should Always Be Handled by Experts

Inspecting machinery without the proper knowledge or attempting to assess damage before experts can evaluate it, is far riskier than many realize. Such actions can not only cause further damage and increase repair costs, but they can also jeopardize your ability to make insurance claims due to disrupted documentation processes. On top of that, there is a real risk to the safety of anyone nearby if precautions are not strictly observed.

This is where BELFOR Thailand steps in. As specialists in machinery condition inspections and plant damage assessments, we combine deep expertise with advanced technology to ensure thorough and accurate evaluations. Our team can detect both visible and hidden damage, provide safe recovery solutions to restore your machinery to working condition, and produce detailed, reliable damage reports that support your insurance claims with confidence. When it comes to protecting your assets and ensuring workplace safety, trusting experienced professionals is not just recommended; it’s essential.