Chemical Leaks in Semiconductor Manufacturing: How Contamination Impacts Yield and Cleanroom Integrity

Key Takeaways

- Chemical leaks can quickly escalate into broader operational issues, introducing airborne and surface contaminants that disrupt production and damage sensitive equipment.

- Even minor particle contamination can lead to significant product defects, often undetectable until late-stage testing, which results in material waste and batch rejections.

- Cleanroom environments are highly sensitive to changes in air quality and pressure, and any breach requires immediate intervention to prevent non-compliance and economical losses.

- Specialist decontamination services offer a fast, structured response, helping industrial facilities recover efficiently while limiting reputational and financial risk.

Introduction

In semiconductor manufacturing, maintaining strict environmental control is essential to ensure product integrity and operational reliability. Chemical leaks pose a significant risk, often leading to widespread contamination that affects both equipment performance and wafer output. These incidents can compromise cleanroom standards and disrupt production timelines. For manufacturers in Asia, the consequences of contamination and yield loss can be substantial.

This article examines how chemical leaks affect production environments and why timely decontamination is critical for effective recovery.

How Chemical Leaks Lead to Widespread Contamination Risks

Chemical leaks in semiconductor environments often result in more than localised damage. When corrosive substances escape containment, they react with surrounding materials, producing airborne particles and chemical vapours. These contaminants pose a serious threat in a semiconductor clean room, where even minute particle exposure can disrupt critical processes. Once released, they spread rapidly through ventilation systems and process tools, increasing the risk of defects and operational downtime across the facility.

What Role Does Corrosion Play in Cleanroom Contamination?

Leaked chemicals can initiate corrosive reactions on metal surfaces, production equipment, and ventilation systems. As corrosion advances, it degrades structural materials and generates secondary contaminants such as dust particles. These particles may remain airborne or accumulate on critical surfaces, increasing the risk of cross-contamination to the product being manufactured. Without prompt and comprehensive semiconductor cleaning, residual contamination can compromise ongoing processes and reduce production yields.

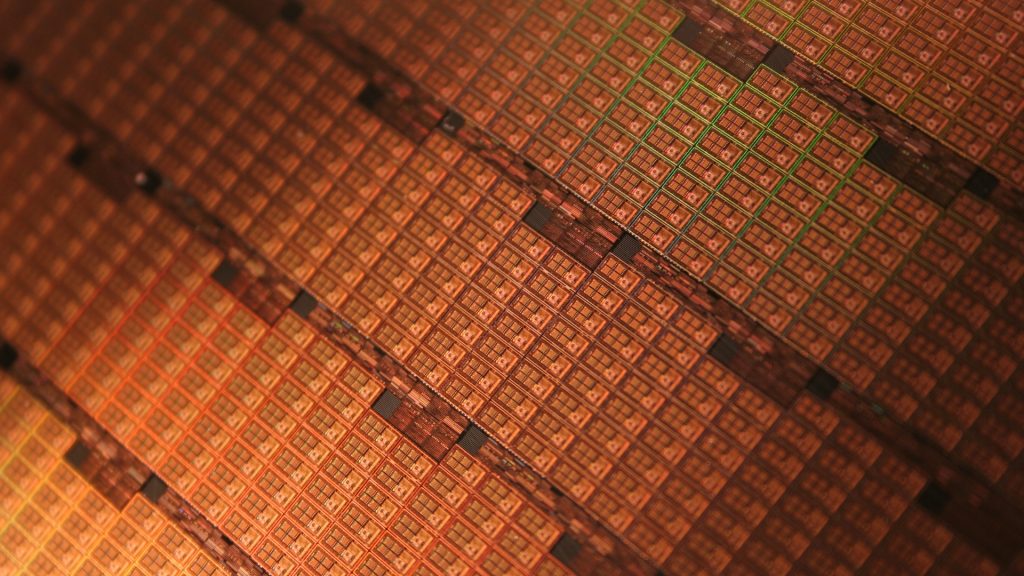

How Does Particle Contamination Affect Wafer Yield?

When contamination enters the production environment, its effects are often not immediately visible. Particles that settle on wafers or infiltrate process chambers can cause defects such as pattern irregularities or short circuits. These issues may only be identified during final testing, by which time multiple wafers may already be compromised. Contamination and yield loss frequently result in the scrapping of entire batches, impacting delivery schedules, increasing material waste, and affecting downstream fulfilment.

Can Cleanroom Standards Be Maintained After a Leak?

Semiconductor cleanrooms operate under stringent classification standards that regulate particle count, air pressure, temperature, and relative humidity. A chemical leak introduces airborne particles and vapours that can disrupt these tightly controlled conditions. Such deviations often necessitate immediate shutdowns for containment, assessment, and remediation. Thorough cleanroom decontamination techniques are critical for reinstating cleanroom environment and ensuring the facility is ready to resume operations. Delays in response increase the risk of further damage to the cleanroom and equipment within long-term shutdown and reputational impact.

What Are the Hidden Costs of Delayed Decontamination?

The consequences of a chemical leak or particle contamiation go far beyond immediate material loss. When cleanroom conditions are compromised, each hour of downtime contributes to production delays, increased remediation labour, and extended equipment recovery. Effective decontamination requires both surface cleaning and air system purification, often involving specialised processes and controlled re-entry protocols. Without rapid containment and proper isolation, contamination and yield loss can persist across production cycles, leading to repeated cleaning, additional rework, and escalating operational costs.

Why Professional Decontamination Support Is Crucial

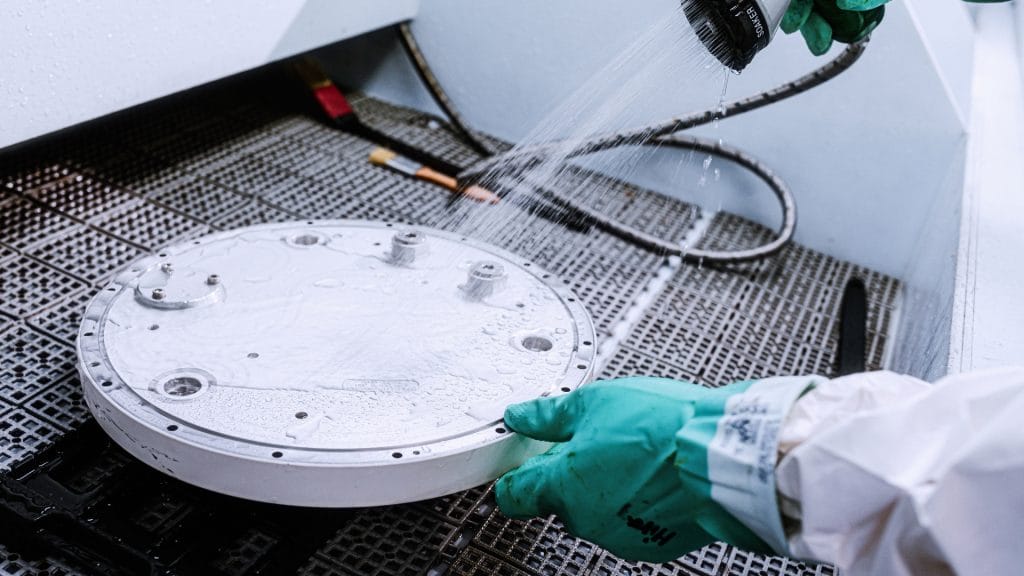

In environments where precision and cleanliness are essential, professional intervention is the most effective way to manage chemical leaks and/or particle contamination. Companies such as BELFOR provide specialised expertise in managing chemical leaks and contamination events. Their teams are equipped to assess the extent of contamination, isolate affected areas, and carry out detailed cleaning processes to restore cleanroom compliance. Leveraging advanced equipment and validated protocols, professional support helps prevent a recurrence, limits production disruption and protects overall output quality.

Reducing the Risk of Contamination and Yield Loss

Chemical leaks present serious operational risks in semiconductor manufacturing, potentially compromising product quality, regulatory compliance, and production continuity. Contamination and yield loss can escalate quickly without a well-executed response. Prompt containment and expert decontamination are essential to limit the spread, protect critical infrastructure, and restore cleanroom integrity.

BELFOR offers specialised decontamination services tailored for semiconductor environments. If your facility has experienced a chemical incident, contact us to support recovery and maintain production reliability.