Why Restoring Damaged Equipment Beats Replacing It: A Smarter Path to Recovery

Introduction

In the aftermath of a disruption, companies often need to make swift decisions about how to manage damaged machinery and critical assets. Replacement can appear to be the safer option, and some vendors position it as the most straightforward route. However, this assumption can result in longer recovery timelines, higher capital expenditure, and avoidable material waste at a time when organisations require certainty and operational stability.

Restoring equipment plays a central role in sustainable disaster recovery, particularly for businesses managing compressed timelines and limited resources. It helps organisations bypass procurement delays, mitigate exposure to global supply chain constraints, and retain control over operational restart. Many companies have found that when stock shortages or extended lead times occur, restoration becomes the only viable path to preventing prolonged downtime.

Restoration also aligns with broader operational and asset-management priorities. Through structured equipment restoration services, organisations can stabilise affected machinery, address contamination promptly, and reduce the long-term impact of fire, water, or environmental exposure. When carried out early, restoration efforts can be coordinated with wider damage restoration activities to prevent further deterioration and preserve the value of essential assets.

Taken together, these factors show why restoration merits close consideration. It strengthens financial planning, reduces operational disruption, and supports environmental responsibility within a single recovery pathway. Its contribution to sustainable disaster recovery is especially relevant to organisations seeking predictable, resilient recovery outcomes.

In this guide, we will examine how restoration can outperform replacement across financial, operational, and sustainability dimensions, giving decision makers a clearer foundation for developing a robust recovery strategy.

Key Takeaways

- Disasters can disrupt multiple layers of mobile communication infrastructure, from physical towers to underground systems, requiring comprehensive and coordinated recovery efforts.

- Contaminants like water and debris pose serious risks to sensitive equipment, potentially leading to long-term system failures if not addressed promptly and thoroughly.

- Restoration work often involves complex logistics, with technicians navigating varied and challenging environments to access and repair impacted sites.

- Connectivity is crucial for emergency services and public safety, making swift recovery a priority not just for businesses but also for the continued functioning of essential community services.

Restoration vs Replacement: Weighing the Real Costs

Understanding the practical difference between restoring and replacing damaged equipment is a critical step in effective recovery planning. Both options can return machinery to service, but each carries distinct operational, financial, and environmental consequences. Assessing the real cost of replacement alongside the benefits of restoration enables organisations to make decisions that protect operational stability, manage expenditure responsibly, and strengthen sustainable disaster recovery efforts. Restoration also contributes directly to business continuity after disasters, particularly when coordinated with essential support measures such as building disinfection services to stabilise affected facilities and minimise further risk.

The Hidden Costs of Replacing Damaged Equipment

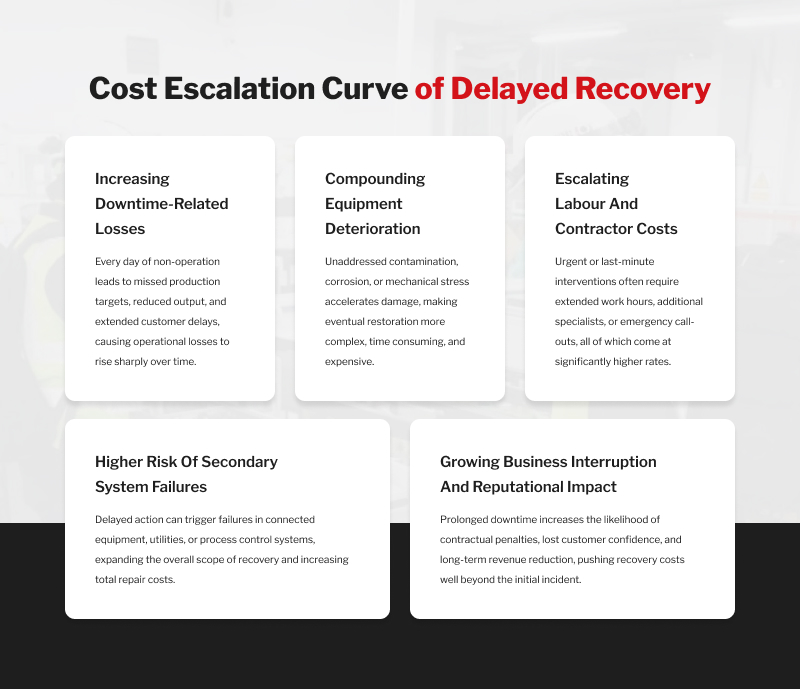

Full equipment replacement may appear straightforward, yet the practical realities often reveal a far more complex and costly process. Lead times can extend for weeks or months as procurement teams secure quotations, place orders, arrange imports, and coordinate installation. During this period, essential operations remain idle, amplifying downtime and affecting overall productivity in ways that many organisations underestimate. This delay can also slow progress toward sustainable disaster recovery, particularly when long supply chains restrict the ability to restart operations.

Capital expenditure becomes a significant consideration when the costs of replacement outweigh the benefits of restoring equipment to a safe working condition. Many businesses misjudge the true cost of equipment replacement, especially when a structured assessment might show that the asset is recoverable. Opting for replacement without a detailed evaluation can strain budgets unnecessarily and divert funds from other strategic priorities, creating challenges that extend well beyond the immediate incident.

Further complications arise when older machinery models are discontinued or unavailable. Organisations may face forced upgrades, incompatible components, migration to new control systems, and staff retraining. These unplanned adjustments introduce additional costs, slow recovery timelines, and create operational uncertainty. For companies aiming to support sustainable disaster recovery, these disruptions place added pressure on both financial and operational resources.

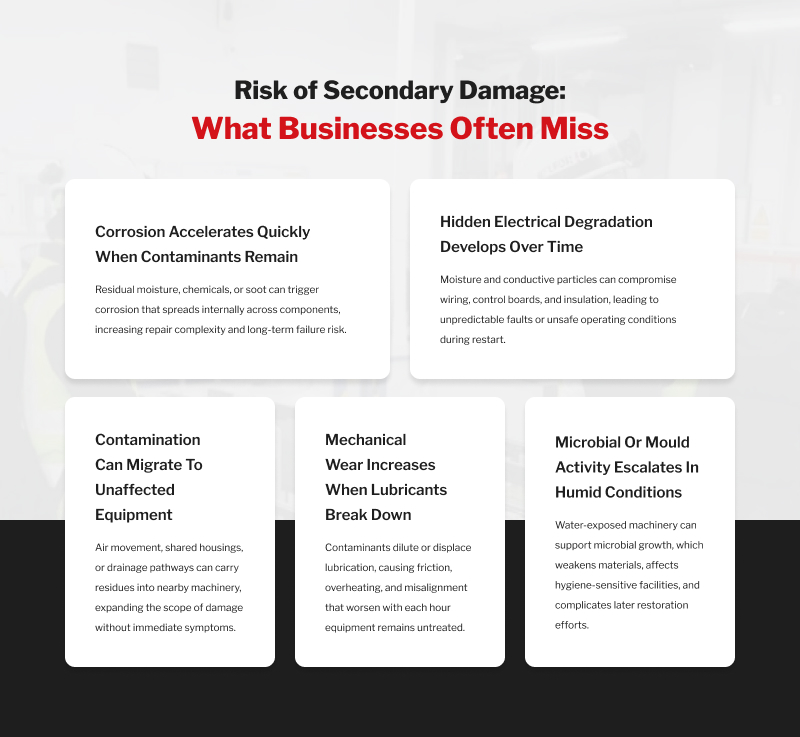

In environments affected by contamination, structural impacts, or complex mechanical failures, early planning around machinery recovery solutions can help stabilise equipment and reduce the scale of loss. When coordinated alongside disaster restoration activities, these efforts limit secondary damage and preserve asset value. This integrated approach supports continuity and aligns with the broader objectives of sustainable disaster recovery, offering a more predictable, controlled path than full equipment replacement.

Restoration as a Practical and Financially Sound Alternative

Restoration provides a practical and efficient route for organisations aiming to resume operations without incurring the substantial capital expenditure associated with full equipment replacement. Skilled recovery teams can assess the condition of damaged assets, stabilise affected components, and perform targeted repairs that restore functionality far faster than the procurement and installation of new machinery. This speed is especially valuable for businesses that depend on continuous production or time-sensitive operations.

The restoration process typically involves detailed inspection, controlled decontamination, component-level repair, and performance testing to verify operational integrity. This structured approach contributes directly to sustainable disaster recovery by extending the useful life of existing equipment and reducing the need for new manufacturing. For many organisations, restored machinery can operate at pre-incident standards, enabling a timely and dependable return to full productivity.

From a financial standpoint, restoration is frequently more cost-effective. Avoiding procurement cycles, import delays, and installation expenses allows organisations to manage budgets more tightly and allocate resources toward other critical operational needs. This is particularly advantageous for companies with limited insurance coverage or exposure to high-risk environments where rapid operational recovery is essential.

Restoration also aligns with broader sustainable recovery strategies, helping organisations reduce waste, conserve materials, and maintain more responsible resource management during periods of disruption. When carried out alongside appropriate environmental and safety controls, restoration becomes an asset-management approach that supports long-term operational resilience.

In more complex recovery scenarios, restoration integrates well with complementary services, such as biohazard cleanup, ensuring that damaged equipment is handled in a stabilised, safe environment. This reduces the likelihood of secondary contamination and helps ensure that repairs progress efficiently and reliably. These combined measures strengthen the overall recovery effort and support the organisation’s goals for sustainable disaster recovery.

How Replacement Delays Disrupt Recovery Timelines

Replacing damaged machinery often introduces delays that organisations cannot fully manage. Manufacturing queues, freight backlogs, and administrative requirements such as customs clearance frequently extend delivery timelines well beyond initial projections. These delays result in prolonged operational downtime, reduced productivity, and disruptions to critical processes that may already be under strain.

For companies that rely on specialised, customised, or high-value machinery, long replacement lead times can result in missed production targets and difficulties meeting customer commitments. Extended downtime also increases financial risk and can weaken customer confidence, particularly in industries where reliability and speed of response influence long-term business relationships. Such pressures can slow progress toward sustainable disaster recovery, especially when operational teams remain dependent on equipment that cannot be replaced quickly.

Restoration offers a more immediate route to stabilising operations. Local recovery teams can assess damage, begin repairs, and return equipment to serviceable condition without the delays associated with international supply chains. This approach supports a faster transition back to normal operations and enables organisations to maintain greater control over their timelines and recovery planning.

Timely restoration also contributes directly to sustainable disaster recovery by reducing the need for new manufacturing and allowing companies to reuse existing assets more effectively. This not only shortens downtime but also supports more responsible resource management during high-pressure periods.

The value of restoration becomes even more apparent when it is coordinated with recovery efforts such as storm restoration, where environmental and infrastructure impacts must be addressed alongside equipment damage. By aligning these activities, organisations can prevent further deterioration and restore multiple systems in a structured and efficient manner.

Using restoration within broader business recovery solutions helps organisations maintain operational stability and manage risk more effectively. This integrated approach strengthens the overall recovery framework and supports a quicker and more predictable return to full activity.

The Broader Benefits of Choosing Restoration

Choosing restoration over complete replacement offers advantages that extend well beyond immediate cost savings. It supports environmentally responsible practices, reduces waste, and enables organisations to strengthen long-term asset resilience. Restoration also allows businesses to take a more strategic approach to recovery planning, integrating operational, financial, and sustainability objectives within a single framework. These benefits align closely with the aims of sustainable disaster recovery, helping companies manage resources responsibly while maintaining operational stability. When combined with structured machinery recovery solutions, restoration provides a coordinated and dependable pathway that supports faster and more efficient recovery across the organisation.

Environmental Impact of Replacement vs Restoration

Full equipment replacement often creates a greater environmental burden than many organisations expect. Machinery that could be restored is frequently discarded, contributing to landfill volume or being left in long-term storage. This generates unnecessary waste and places additional pressure on disposal systems already challenged by industrial and commercial demands.

The production of new equipment also carries a high environmental cost. Extracting raw materials, manufacturing components, assembling machinery, and transporting them across borders all contribute to carbon emissions. Packaging and controlled-environment transport add further impact, particularly when the equipment is large, highly specialised, or sensitive to temperature changes.

Restoration offers a more resource-efficient alternative by limiting waste and extending the useful life of existing assets. This approach supports sustainable disaster recovery by lowering emissions, reducing demand for new materials, and helping organisations align their operations with broader environmental and sustainability objectives.

For companies with formal ESG commitments, restoration fits naturally into sustainable recovery strategies, enabling more efficient resource use and improving the overall environmental profile of recovery activities. When restoration is combined with complementary services such as flood damage restoration, it supports safer handling of water-affected machinery, prevents further degradation, and reduces the risk of secondary contamination. This coordinated approach strengthens both the environmental and operational outcomes of the recovery process.

Supporting Business Continuity Through Restoration

Organisations facing operational disruption typically prioritise returning to stable activity as quickly as possible. Restoration supports this objective by offering a practical solution when supply chains are congested, replacement equipment is unavailable, or procurement lead times are uncertain. Skilled recovery teams can stabilise affected machinery on-site and begin targeted repairs immediately, reducing the risk of extended shutdowns and additional operational stress. This speed is essential for organisations working toward sustainable disaster recovery while managing real-time business pressures.

Restoration is particularly valuable in sectors that depend on customised, high-value, or legacy equipment. In these environments, suitable replacement units may be limited or discontinued, making repairs the only feasible option to maintain production schedules. The ability to recover existing machinery helps reduce downtime, prevent workflow disruptions, and avoid the financial impact associated with lengthy procurement cycles.

This approach directly supports sustainable disaster recovery by preserving existing assets, reducing demand on manufacturing and logistics networks, and minimising resource consumption. It also aligns with long-term operational priorities in efficiency, environmental responsibility, and service continuity.

The operational advantages of restoration can be seen clearly in several areas:

Reduction of Business Interruption Period

BELFOR teams focus on restoring equipment and supporting operational restart as quickly as possible. Shorter recovery timeframes allow businesses to minimise disruptions and return to servicing customers sooner.

Reduction of Lost Business Opportunities

Every additional day of downtime increases the likelihood that customers will seek alternative providers. Faster equipment recovery supports consistent service delivery and protects established business relationships, especially in just-in-time environments or when replacement parts are difficult to procure.

Reduction of Recovery Costs

Restoration is a more cost-efficient option than full replacement. This is particularly beneficial for organisations with limited insurance coverage, as it helps manage overall recovery expenditures and supports a more predictable return to normal operations.

Restoration also integrates effectively with broader technical and environmental measures. When paired with decontamination services, for example, it ensures that machinery is repaired within a stable, clean, and controlled environment. This reduces the risk of secondary contamination, protects equipment integrity, and strengthens the reliability of the overall recovery process.

Questions You Might Have

1. Is restoration reliable enough for critical equipment?

Yes. When handled by qualified specialists, restored machinery can operate at pre-loss performance levels. The process contributes directly to sustainable disaster recovery by extending the functional life of existing assets and helping organisations regain operational stability without unnecessary delays.

2. Does restoring equipment void warranties or affect compliance?

Once equipment is damaged in an incident, original manufacturer warranties are typically voided, regardless of the path chosen. Restoration, therefore, does not create additional disadvantage. Reputable providers such as BELFOR offer limited warranties for restored equipment and ensure that all work adheres to relevant safety, compliance, and performance standards. This level of assurance is particularly important for companies working toward sustainable disaster recovery while maintaining regulatory alignment.

3. Why do vendors often favour replacement?

Vendors tend to promote replacement because it fits within their commercial scope. Their operations are structured around selling new units or completing basic repairs, not conducting complex equipment recovery. Replacement is also easier for them to price and process, even when it may not be the most time-efficient or cost-effective solution for the organisation. For businesses prioritising sustainable disaster recovery, these vendor-driven decisions may not align with operational or environmental goals.

4. Can restoration help with sustainability goals?

Yes. Restoration helps organisations meet sustainability commitments by reducing waste, prolonging asset lifespan, and avoiding the environmental impact associated with manufacturing and transporting new machinery. These outcomes support broader ESG objectives and form a key part of long-term sustainable disaster recovery strategies.

5. How do I know when restoration is the better choice?

Restoration is generally the preferred option unless equipment is structurally unsalvageable or unsafe to recover. A professional assessment should always be the first step. This evaluation outlines the extent of the damage, the feasibility of repair, and the expected recovery timeline. Taking this approach ensures that decisions are informed, responsible, and aligned with the organisation’s operational needs and sustainable disaster recovery objectives.

In complex situations, particularly those involving fire damage restoration or wider business continuity after disasters, coordinated assessments help determine the safest and most efficient recovery path.

Conclusion

The decision to replace damaged equipment should never be automatic. Restoration often provides a faster, more sustainable, and more cost-effective route back to operational stability, particularly when organisations face time constraints or limited resources. A structured assessment of restoration feasibility enables businesses to manage recovery across financial, operational, and environmental priorities in a balanced and informed manner.

From a financial standpoint, restoration can help organisations avoid substantial capital expenditure and reduce the long-term costs associated with full equipment replacement. In terms of time, it shortens downtime and supports a faster return to full operational capacity.

Environmentally, restoration aligns with the principles of sustainable disaster recovery, promoting responsible use of existing assets and extending the service life of critical machinery. When supported by appropriate planning and technical expertise, restoration also strengthens long-term organisational resilience by reducing avoidable disruption and preserving continuity.

As recovery expectations evolve, organisations benefit from adopting a recovery-first mindset that emphasises stability, resource efficiency, and long-term operational resilience.

To determine how restoration can support your wider recovery planning, contact BELFOR. Our specialists provide structured assessments that identify what can be safely restored and guide your organisation toward the most effective and responsible recovery pathway.