BELFOR Korea Completes Intensive Precision-Cleaning Training, Minimising Risk Through Data-Driven Restoration

Disaster-restoration specialist BELFOR Korea conducted five-day intensive Precision Cleaning training at its Bucheon headquarters from 21 to 25 April, sharpening the skills of three newly hired technicians. Under company policy, every technician must finish this hands-on and classroom course within their first six months, mastering the entire workflow—from contaminant removal and corrosion treatment to drying and reassembly—using the same check-lists that guide BELFOR’s field operations.

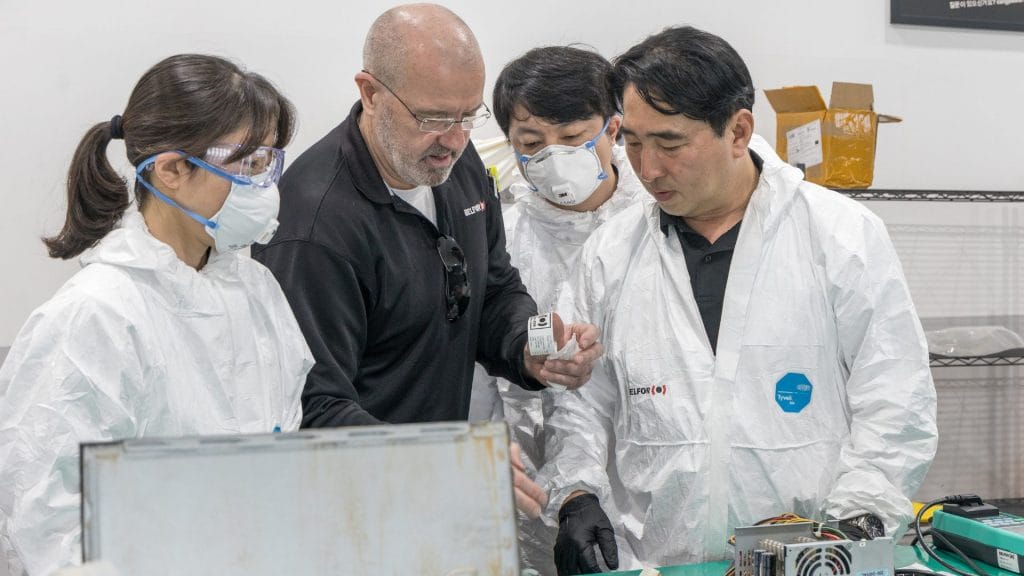

The programme followed the BELFOR Asia standard curriculum. Hyeokjun Kweon, Training Manager at BELFOR Korea, directed the sessions, while John Shanahan, Regional Technical Director for Asia, inspected the class in person to verify compliance with global quality benchmarks. Participants repeated every restoration step on live equipment, internalising the roadmap that precedes actual site deployment: documentation, ESD protection, disassembly, cleaning, drying, reassembly and power-up testing.

“Learning the correct cleaning process early on dramatically reduces secondary contamination and rework risk at a loss scene,” Kwon said. “Thanks to this training, our new technicians are now ready for immediate dispatch to urgent restoration projects.” Shanahan added that “the combination of standardised procedures and measured data delivers the transparency stakeholders expect.”

BELFOR Korea plans two additional sessions in the second half of the year—one in Korea and one in Thailand—to further raise response speed and quality consistency across Asia. Graduates of the course can be on site within four hours of an incident, helping partners cut downtime losses and expedite claims processing