COMMERCIAL SERVICES

- Emergency Response

- Smoke and Soot Removal

- Water Extraction & Drying

- Shrink Wrap

- Mould Removal & Remediation

- General Contracting & Reconstruction

- Document & Media Recovery

- Air Duct Cleaning

- Contents Restoration

- Electronics Restoration

- Equipment & Machinery Repair

- Ultrasonic Cleaning

- Semiconductor Services

- Environmental Services

- Consulting Services

Exposure to water, smoke, or other contaminants can wreak havoc on machine parts. If not promptly cleaned and decontaminated, parts may have to be replaced at great expense – including business downtime.

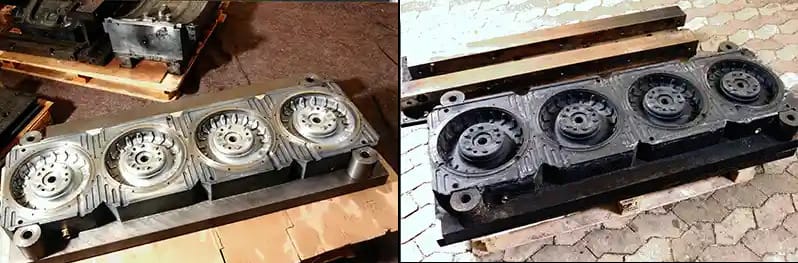

BELFOR provides Ultrasonic Cleaning – the fastest and most effective method available for cleaning and completely de-rusting machine parts, stock (injection molding, tools, gear parts) and semi-finished products.

Ultrasonic Cleaning is a viable alternative to total replacement. Unlike most other companies, BELFOR has an industrial-size Ultrasonic Cleaning Dip Line that can be mobilized and used on-site at most industrial facilities – saving precious recovery time and restoring business operations at a faster pace.

Advantages of Ultrasonic Cleaning

- Unmatched Effectiveness

- Speed

- Cost Savings

- Reduced Downtimes

- Effective at removing contamination within cavities

- Cleaning agents developed by BELFOR specifically for UCS

- Tested in a wide variety of applications following fire and water damage

How Does It Work?

Ultrasonic cleaning uses high frequency sound waves to generate cavitation in the liquid. The resulting energetic bubble action penetrates blind holes, cracks, and recesses to thoroughly remove all traces of contamination adhering or embedded on the solid surface. Contaminants can include dust, dirt, oil, pigments, grease, polishing compounds, flux agents, soot, and more.

Cleaning Sequence

BATH 1: Pre-cleaning and Hot Degreasing

Complete removal of various forms of surface contamination by means of ultrasound and hot cleaning solutions.

BATH 2: Rinsing, Grease/Cleaning, Solution Removal

Rinsing of residual grease/dirt and cleaning solution from the component to avoid cross contamination of subsequent bath.

BATH 3: Corrosion Removal

Complete removal of the corrosion at 55˚C using ultrasound and a gentle, slightly acidic complex de-ruster. Suitable for hardened or polished surfaces.

BATH 4: Rinsing and Acid Neutralization

Residual acid and removed corrosion residue are rinsed off, preparing for the final step.

BATH 5: Water Displacement and Preservation

Water displacement and passivating agents ensure that the metal surfaces do not rust upon exposure to air.

Full Time Dedicated Professionals

We will stand by you to ensure a complete recovery.